Bright Machines is going public via a SPAC-led mixture, it announced this morning. The transaction will see the 3-year-old firm merge with SCVX, elevating gross money proceeds of $435 million in the method.

After the transaction is consummated, the startup will sport an anticipated fairness valuation of $1.6 billion.

The Bright Machines information signifies that the good SPAC chill was not a deep freeze. And the transaction itself, in conjunction with the beforehand introduced Desktop Metal blank-check deal, implies that there’s area in the marketplace for {hardware} startup liquidity via SPACs. Perhaps that can unlock extra late-stage capital for hardware-focused upstarts.

Today we’re first taking a look at what Bright Machines does, after which the monetary particulars that it shared as a part of its information.

What’s Bright Machines?

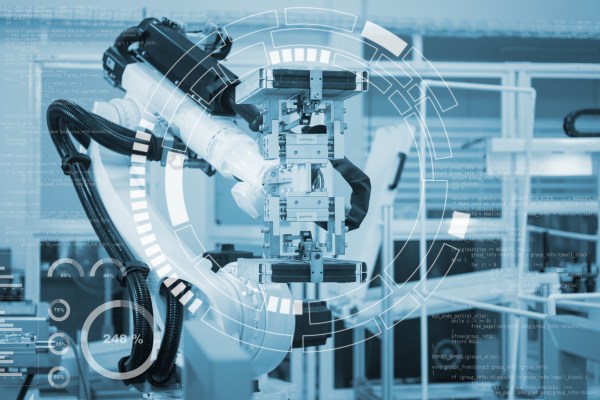

Bright Machines is attempting to unravel a tough downside associated to industrial automation by creating microfactories. This includes a posh mixture of {hardware}, software program and synthetic intelligence. While robotics has been round in one type or one other because the 1970s, for essentially the most half, it has lacked actual intelligence. Bright Machines needs to vary that.

The firm emerged in 2018 with a $179 million Series A, a hefty amount of money for a younger startup, however the firm has a daring imaginative and prescient and such a imaginative and prescient takes in depth funding. What it’s attempting to do is totally remodel manufacturing utilizing machine studying.

At the time of that funding, the corporate introduced in former Autodesk co-CEO Amar Hanspal as CEO and former Autodesk founder and CEO Carl Bass to take a seat on the corporate board of administrators. AutoDesk itself has been attempting to rework design and manufacturing in latest years, so it was logical to convey these two skilled leaders into the fold.

The startup’s thesis is that as an alternative of getting what are basically “unintelligent” robots, it needs so as to add pc imaginative and prescient and a heavy dose of sensors to convey a data-driven automation method to the manufacturing facility ground.